Transforming waste into resources

Transforming waste into resources

We’re exhibiting at Tire Technology Expo

Hannover, March 19, 20 & 21, 2024

Siemes Ag /Pyrum Innovations AG

Stand no. 8058

„Die reinste Form des Wahnsinns ist es, alles beim Alten zu lassen und gleichzeitig zu hoffen, dass sich etwas ändert.“ (Albert Einstein)

Die Pyrum Innovations AG

Die Pyrum Innovations AG ist ein zukunftsweisendes Recycling- und Anlagenbauunternehmen mit Sitz in Dillingen/Saar (Deutschland).

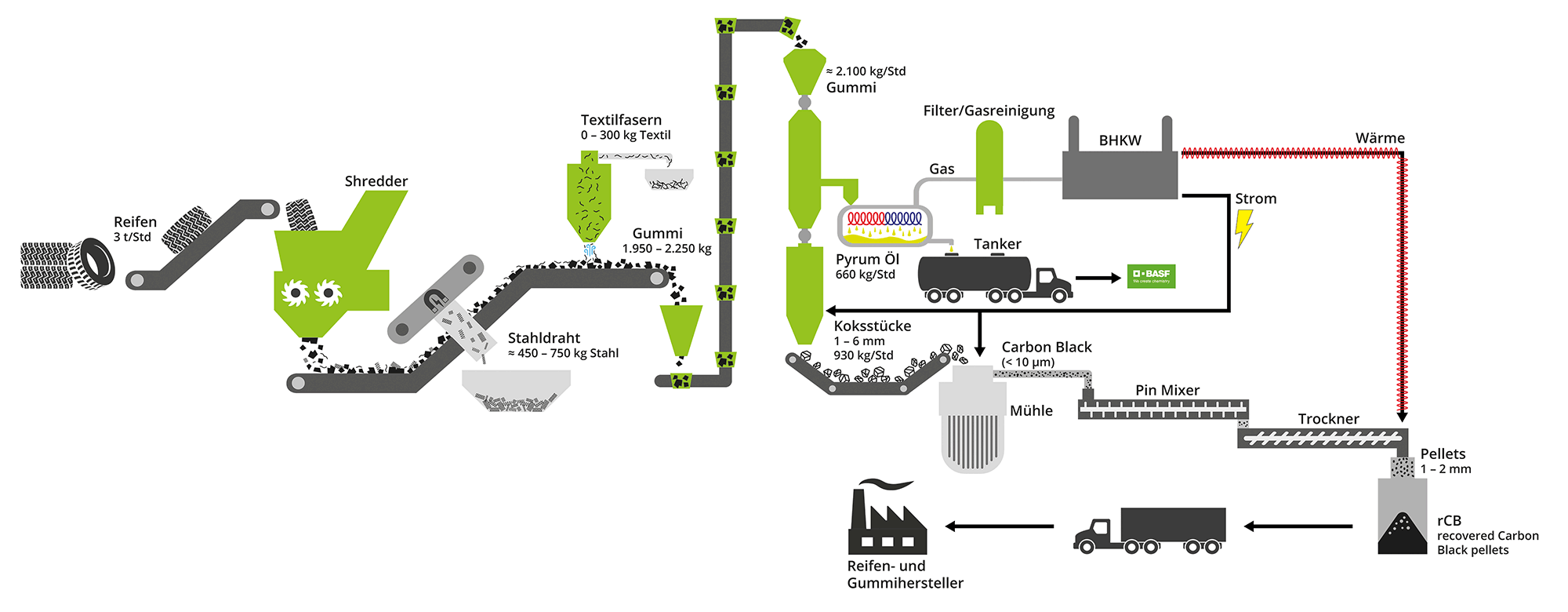

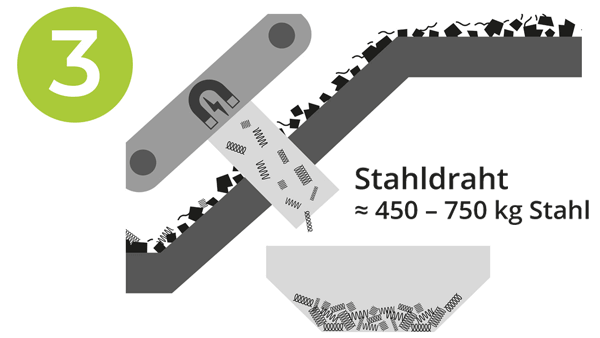

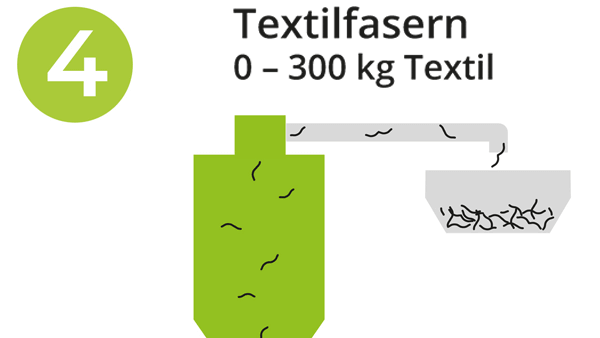

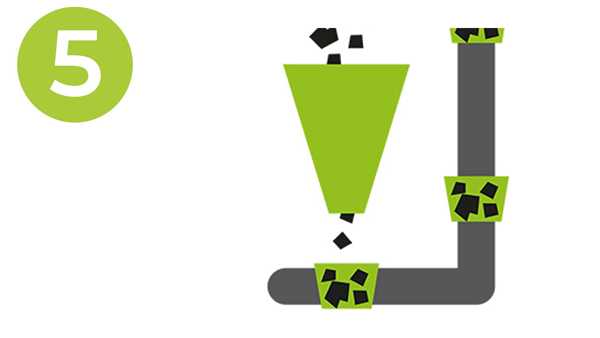

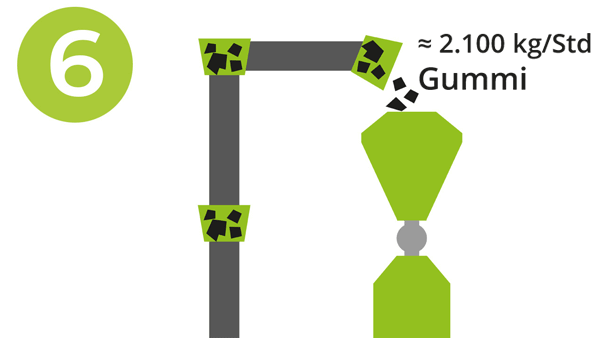

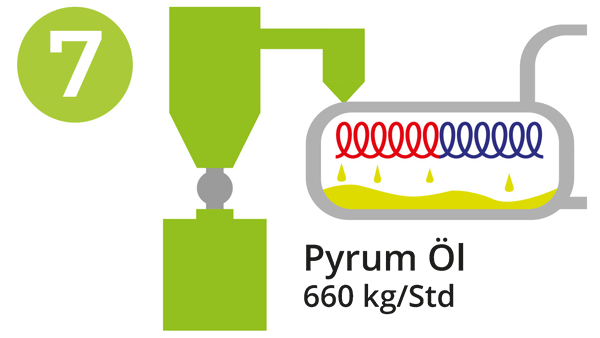

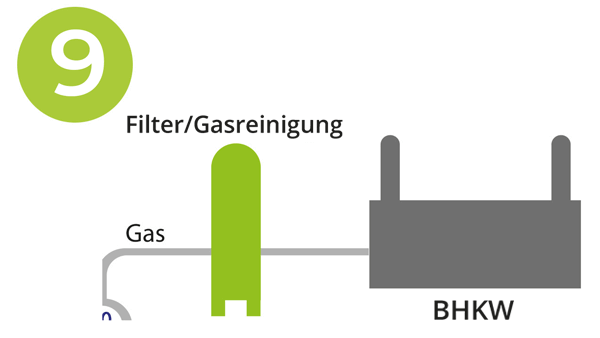

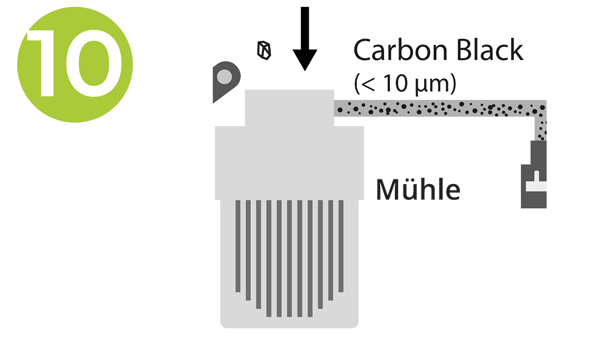

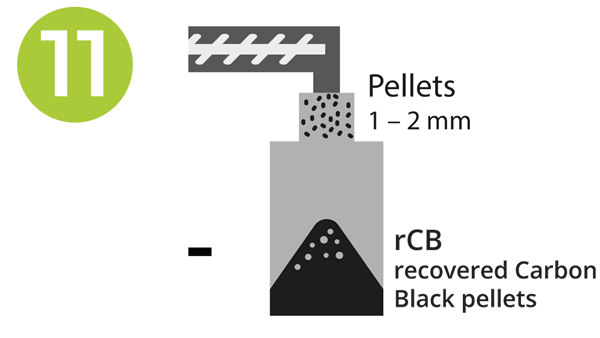

Auf Basis unseres weltweit patentierten, einzigartigen Thermolyse-Verfahrens entwickeln, bauen und betreiben wir innovative Recyclinganlagen. Mit diesen lassen sich aus Altreifen, Gummi und Kunststoffabfällen auf umweltverträgliche Art Rohstoffe mit hoher Qualität gewinnen und erneut dem Wertstoffkreislauf zuführen. Zu den gewonnenen Sekundär-Rohstoffen gehören u. a. Thermolyseöl mit REACH-Zertifizierung sowie recovered Carbon Black (rCB).

Die innovativen Thermolyse-Recyclinganlagen werden weltweit vermarktet und an die Pyrum-Vertragspartner ausgeliefert.

Im September 2020 hat sich die BASF im Rahmen ihres ChemCyclingTM-Projekts an der Pyrum Innovations AG beteiligt und garantiert die Abnahme des sowohl in den eigenen Anlagen als auch in den Werken der Vertragspartner erzeugten Thermolyseöls.

Technologie

Lösungen

Umwelt

Vorteile der Pyrum Thermolyse-Technologie

Aktuelles

Der Pyrum-Gedanke

Die Pyrum Innovations AG entstand 2008 aus einer Idee von vier Freunden in einer 9 m² großen Gartenlaube. Heute sind wir eines der führenden Thermolyse-Unternehmen mit weltweiten Patenten.

Seit der Unternehmensgründung haben wir alles selbst entwickelt, geplant und gebaut – vom eigenen Labor bis hin zum großindustriellen Recyclingwerk. Die größten Hürden auf dem angestrebten Weg zum Weltmarktführer haben wir bereits gemeistert.

Die Pyrum-Geschichte zeigt, dass nichts unmöglich ist, solange man an sich und seine Sache glaubt. Wir haben das Thermolyse-Verfahren zur Überraschung vieler Zweifler erfolgreich im industriellen Maßstab realisiert – ganz nach dem Motto: “Alle sagten das sei unmöglich, dann kam jemand, der das nicht wusste, und hat es einfach gemacht”.

Wir werden auch in Zukunft unseren Werten treu bleiben, über den Tellerrand hinausschauen und neue Lösungen entwickeln, um einen Beitrag dazu zu leisten, die Abfall- und Umweltprobleme der Welt zu lösen.

Der Vorstand