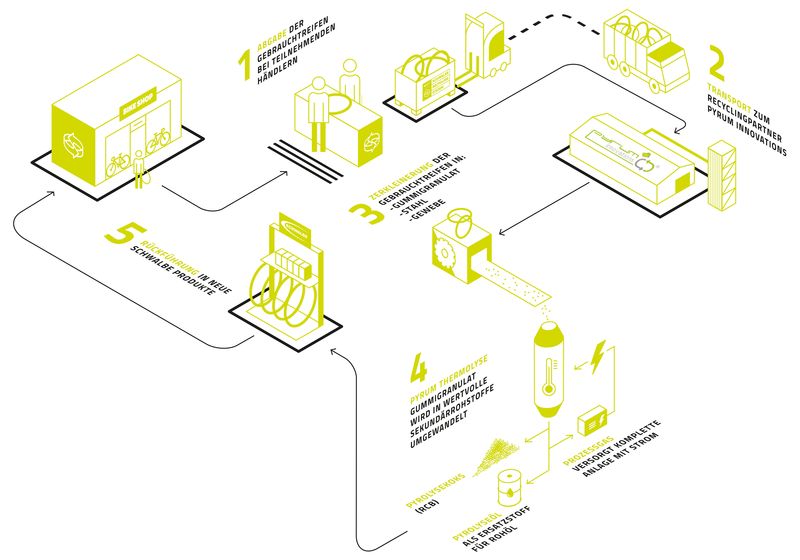

Our innovative Schwalbe recycling system is used for the mechanical processing and pyrolytic recycling of used bicycle tyres in our thermolysis plant.

By loading the video, you accept YouTube’s privacy policy.

Learn more

Ralf Bohle GmbH, which produces the Schwalbe brand, and Pyrum Innovations AG showcased a new recycling system for used bicycle tyres at the launch of Eurobike, the world’s largest bicycle trade fair, in Frankfurt. The ‘Schwalbe Recycling System’, which was developed in close coöperation with the Technical University of Cologne, enables the complete recycling of used tyres of all brands.

Schwalbe has established a collection network for used bicycle tyres. The specially developed Schwalbe Recycling Box is available at all participating specialist dealers. In its pyrolysis plant, Pyrum is responsible for the mechanical processing and pyrolytic recycling of used tyres, a process that transforms old tyres into new ones. The process cuts CO2 by 80%.

Frank Bohle, Managing Director of Ralf Bohle GmbH: ‘Like back in 1983 when we launched the first Schwalbe Marathon, we are at the start of a long journey in tyre recycling. We are extremely grateful to Pyrum for their pioneering work in the field of pyrolysis.’ Ralf Bohle GmbH is Europe’s market leader for bicycle tyres and inner tubes. Sustainability has always been among the company’s most important qualities and values.

Pascal Klein, CEO of Pyrum Innovations AG: ‘With its Schwalbe brand, Bohle is the perfect fit for our fully sustainable business model. Thanks to this new recycling system, we are helping to make the bicycle an even more sustainable means of transport.’