Transforming waste into resources

Transforming waste into resources

We’re exhibiting at Tire Technology Expo

Hanover, March 19, 20 & 21, 2024

Siemes Ag /Pyrum Innovations AG

Booth no. 8058

“The purest form of madness is to leave everything as it is and at the same time hope that something will change.” (Albert Einstein)

Pyrum Innovations AG

Pyrum Innovations AG is a forward-looking recycling and plant engineering company based in Dillingen/Saar (Germany).

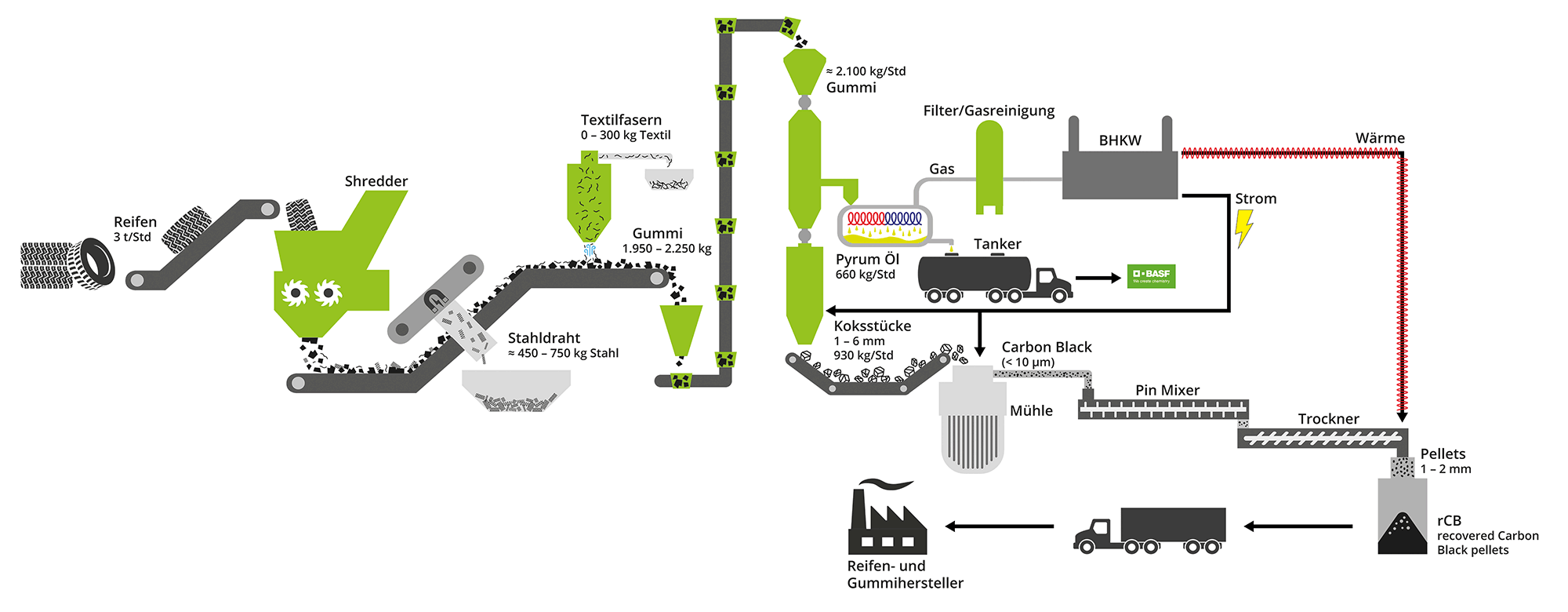

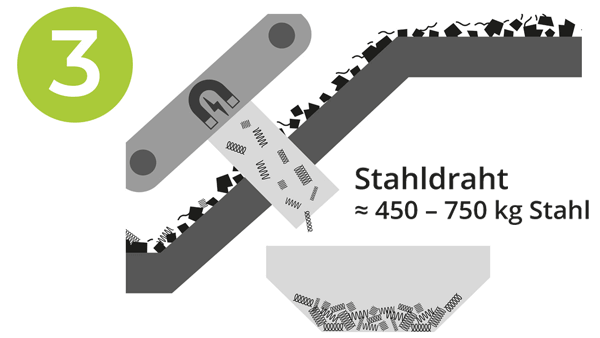

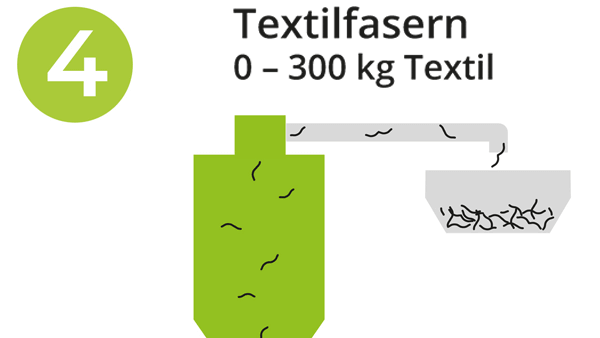

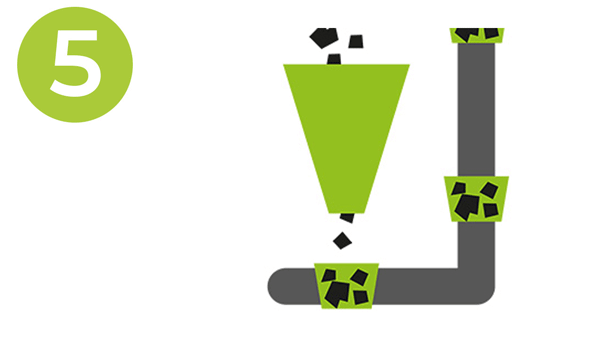

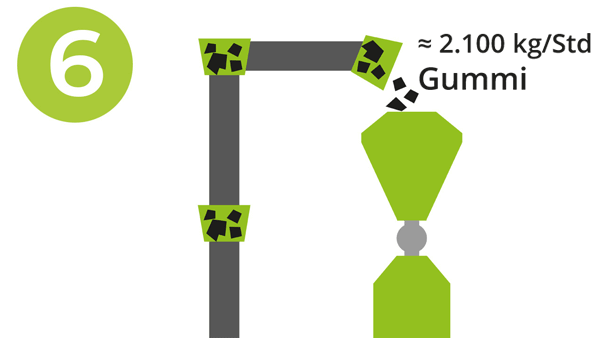

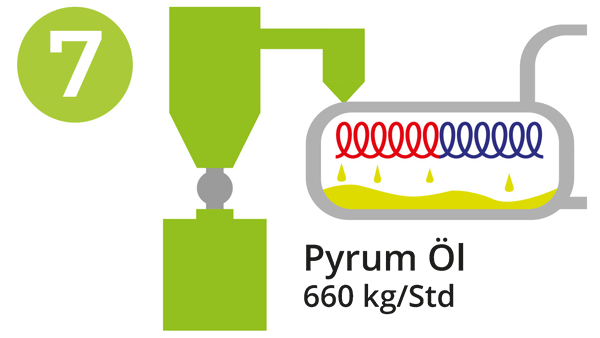

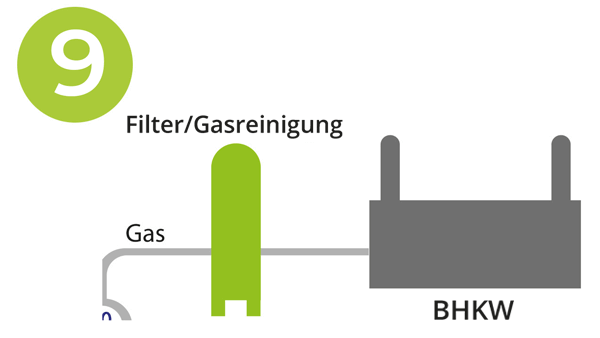

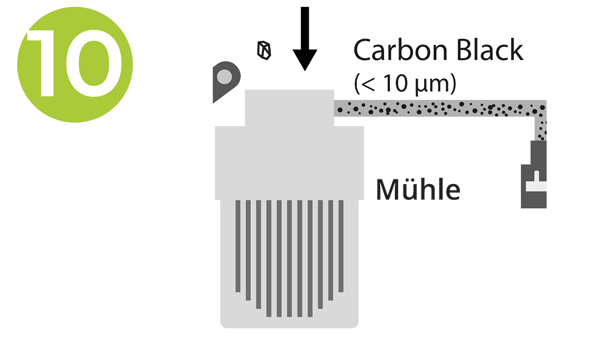

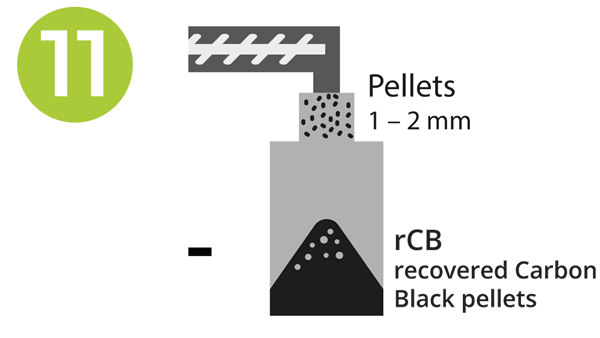

We develop, build and operate innovative recycling plants based on our globally patented, unique thermolysis process. These allow us to recover high-quality raw materials from used tyres, rubber and plastic waste in an environmentally friendly way and return them to the materials cycle. The secondary raw materials obtained include thermolysis oil with REACH certification and recovered carbon black (rCB).

The innovative thermolysis recycling systems are marketed worldwide and supplied to Pyrum’s contract partners.

In September 2020, BASF BASF acquired a stake in Pyrum Innovations AG as part of its – ChemCyclingTM-Pyrum Innovations AG and guarantees the purchase of the thermolysis oil produced both in its own plants and in the plants of its contractual partners.

Technology

Solutions

Environment

Advantages of Pyrum thermolysis technology

Latest news

The Pyrum concept

Pyrum Innovations AG was founded back in 2008, the brainchild of four friends, and was initially based out of a 9 m² garden shed. Today we are one of the leading thermolysis companies with worldwide patents.

Since the company’s foundation, we have developed, planned and built everything ourselves – from our own laboratory to the large-scale industrial recycling plant. We have already overcome the biggest hurdles on our path to becoming the global market leader.

Pyrum’s story proves that nothing is impossible as long as you believe in yourself and your cause. To the surprise of many doubters, we have successfully implemented the thermolysis process on an industrial scale. As the saying goes: ‘Everyone said it was impossible, then someone who didn’t know that came along and just did it.’

We will remain true to our values in the future, think outside the box and develop new solutions in order to make a contribution to improving the Solving the world’s waste and environmental problems.

The Executive Board